1. Úvod

This manual provides essential information for the safe and efficient installation, operation, and maintenance of your U.S. Solid 2-Inch 110V AC Brass Electric Solenoid Valve. Please read these instructions thoroughly before installation and retain this manual for future reference.

The U.S. Solid 2-Inch 110V AC Brass Electric Solenoid Valve is a normally closed, two-port, two-position valve designed for controlling the flow of various media. Constructed from industrial-grade brass with a Viton seal, it offers corrosion resistance and is suitable for a wide range of applications, including those involving gasoline, diesel fuel, kerosene oil, natural gas, air, and drinking water.

This image displays the U.S. Solid 2-inch 110V AC Brass Electric Solenoid Valve from a front-side perspective, highlighting its brass body and black solenoid coil with red electrical wires.

2. Bezpečnostní informace

- Elektrická bezpečnost: Ensure all electrical connections are made by a qualified professional and comply with local electrical codes. Disconnect power before installation or maintenance.

- Pressure and Temperature: Nepřekračujte maximální provozní tlak ani teplotu specifikovanou pro tento ventil.

- Kompatibilita médií: Verify that the valve material (brass) and seal material (Viton) are compatible with the fluid or gas being controlled.

- Pracovní cyklus: This valve is NE a continuous duty valve. It should not be in continuous use for more than 10 hours in a single cycle. Exceeding this limit can shorten the valve's lifespan and may cause the solenoid coil to burn out. For applications requiring continuous duty, consider U.S. Solid Motorized Ball Valves.

- Směr toku: Always observe the flow direction arrow stamped on the valve body to ensure correct installation. Incorrect installation can lead to improper operation.

- Upozornění Kalifornie Proposition 65: This product can expose you to Lead, which is known to the State of California to cause cancer. For more information, visit www.P65Warnings.ca.gov.

This graphic provides crucial information: the valve's IP65 ingress protection rating (dust-tight, protected from water jets), details on VITON and NBR seal materials and their temperature ranges, a warning against continuous operation for more than 8 hours to prevent overheating, and the California Proposition 65 warning regarding lead exposure.

3. Vlastnosti produktu

- Odolná konstrukce: Made from industrial-grade brass for corrosion resistance and suitability in various environments.

- Viton Seal: Equipped with a high-performance Viton seal, offering excellent resistance to high temperatures and corrosive chemicals, including gasoline, diesel fuel, oils, and lubricants.

- Rychlá odezva: Opens and closes in less than 3 seconds when actuated, providing instantaneous flow control.

- Normálně zavřený provoz: The valve remains closed when de-energized and opens when electrical power is applied.

- Široký rozsah použití: Suitable for use with water (including drinking water), air, natural gas, gasoline, diesel fuel, and kerosene oil.

- Vysokocyklová životnost: Engineered for over a million cycles under proper operating conditions and maintenance.

4. Specifikace

| Specifikace | Detail |

|---|---|

| Číslo modelu | USS-SV-Parent05 |

| Typ ventilu | 2cestný, normálně uzavřený |

| Materiál těla | Mosaz |

| Materiál těsnění | Viton |

| svtage | 110V AC |

| Velikost vstupního/výstupního připojení | 2 palce |

| Typ připojení | NPT (National Pipe Tapered) |

| Maximální provozní tlak | 101 PSI (libra na čtvereční palec) |

| Operating Temperature Range (Viton) | -10 °C až 120 °C (14 °F až 148 °F) |

| Doba odezvy | Méně než 3 sekundy |

| Hodnocení ochrany proti vniknutí (IP). | IP65 (Dust-tight, protected from water jets) |

| Počet portů | 2 |

| Rozměry položky (D x Š x V) | 7.9 x 6.9 x 5 palce |

| Hmotnost položky | 9.3 libry |

| Osvědčení | CE |

An illustration detailing the physical dimensions of the solenoid valve, including its height (7.1 inches), width (5.3 inches), and coil width (3.6 inches), along with its weight (6.4 lbs).

Detailní view of the label on the solenoid coil, indicating model number (USS2-00116), orifice size (50mm), pipe size (2"), volts (AC110V), temperature range (-10°C to 120°C), and pressure ratings for air/water and oil.

5. Nastavení a instalace

5.1 Kontroly před instalací

- Inspect the valve for any signs of damage during shipping.

- Ensure the valve's specifications (voltage, pressure, temperature, media compatibility) match your application requirements.

- Confirm that the power supply is disconnected before beginning installation.

5.2 Montáž ventilu

- Identify the inlet and outlet ports. The valve body has a flow direction arrow stamped on it. Ensure the valve is installed so that the fluid or gas flows in the direction indicated by the arrow.

- Apply appropriate thread sealant (e.g., PTFE tape or pipe dope) to the NPT threads of your piping connections.

- Thread the valve onto the pipes, ensuring a secure, leak-free connection. Do not overtighten, as this can damage the valve or threads.

- Mount the valve in a position that allows for easy access for electrical connections and future maintenance. The valve can be mounted in any orientation, but vertical mounting with the solenoid coil upwards is generally recommended for optimal performance and lifespan.

Strana view of the solenoid valve, showing the brass body, the black solenoid coil, and the electrical connections. A flow direction arrow is visible on the brass housing, indicating proper installation orientation.

5.3 Elektrické připojení

- Ujistěte se, že je napájení VYPNUTÉ.

- Connect the two electrical wires from the solenoid coil to your 110V AC power source. This valve is not polarity sensitive for AC power.

- Secure all electrical connections to prevent accidental disconnection or short circuits.

- Once connections are complete, you may restore power and test the valve's operation.

6. Návod k obsluze

The U.S. Solid 2-Inch 110V AC Brass Electric Solenoid Valve is a normally closed valve. This means it will remain in the closed position, blocking flow, when no electrical power is supplied to the solenoid coil.

- Otevření ventilu: Apply 110V AC electrical power to the solenoid coil. The valve will open rapidly (in less than 3 seconds), allowing fluid or gas to flow through.

- Zavření ventilu: Remove the 110V AC electrical power from the solenoid coil. The valve will close rapidly (in less than 3 seconds), stopping the flow.

Important Operating Considerations:

- Pracovní cyklus: As noted in the safety section, this valve is designed for intermittent use. Avoid continuous operation for more than 10 hours in a single cycle to prevent overheating and premature failure of the solenoid coil.

- Media Purity: While the valve is robust, using clean media free of large particulates will help prolong its lifespan and prevent blockages.

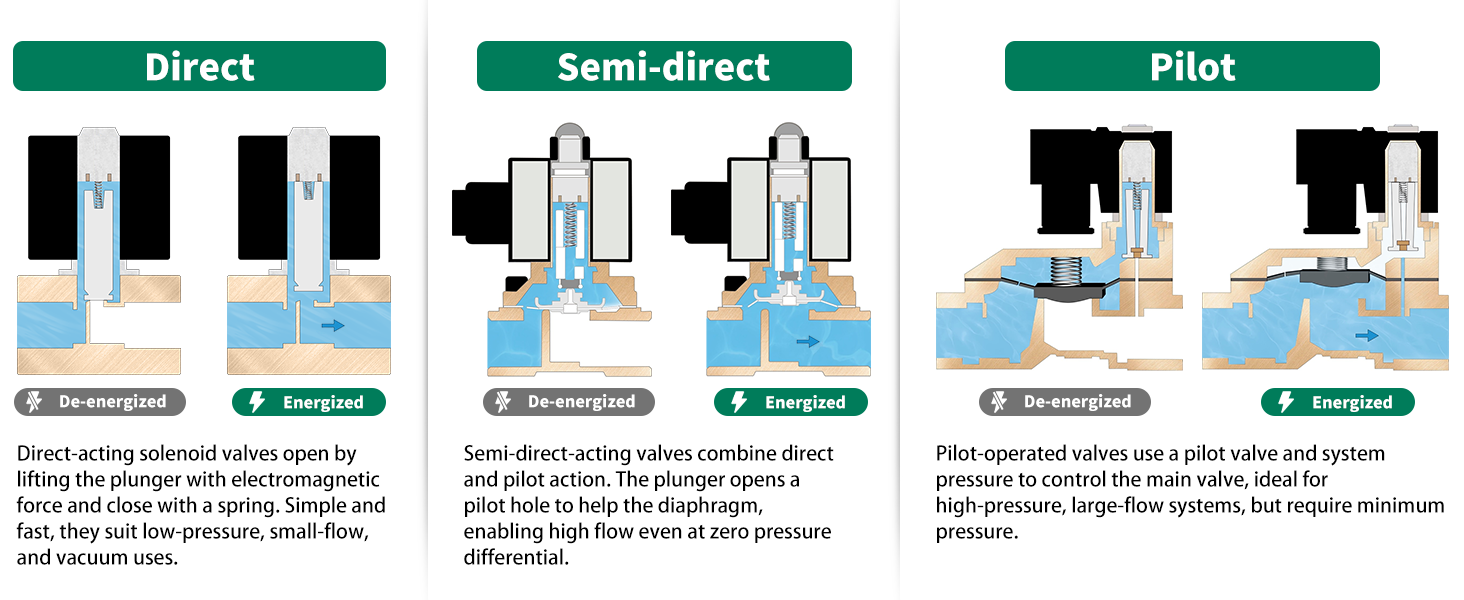

A diagram explaining the operational principles of different solenoid valve types: direct-acting, semi-direct-acting, and pilot-operated, showing how they open and close when de-energized and energized. This U.S. Solid valve operates as a direct-acting or semi-direct valve.

7. Údržba

Regular maintenance helps ensure the longevity and reliable operation of your solenoid valve.

- Pravidelná prohlídka: Periodically inspect the valve for any signs of leaks, corrosion, or damage to the electrical wiring.

- Čištění: If operating with media that may leave residue, occasional cleaning of the internal components may be necessary. Ensure power is disconnected and pressure is relieved before disassembling the valve.

- Výměna těsnění: The Viton seal is durable but may eventually wear out. If leaks occur around the valve body or plunger, the seal may need replacement. Contact U.S. Solid support for replacement parts.

- Cívka solenoidu: The solenoid coil is generally maintenance-free. If the valve fails to actuate, check the electrical connections and ensure the coil is receiving the correct voltage.

8. Řešení problémů

| Problém | Možná příčina | Řešení |

|---|---|---|

| Ventil se neotevírá, když je pod napětím | Žádné napájení cívky; Nesprávný objemtage; Damaged coil; Obstruction in valve; Incorrect flow direction | Check electrical connections and power supply; Verify correct 110V AC voltage; Inspect coil for damage (replace if necessary); Disassemble and clean valve; Reinstall valve in correct flow direction. |

| Ventil se nezavírá, když je bez napětí | Coil remains energized; Obstruction preventing closure; Damaged seal/internal components | Check power supply to ensure it's disconnected; Disassemble and clean valve; Inspect and replace seals or internal components if damaged. |

| Únik z těla ventilu | Loose connections; Damaged seals; Cracked valve body | Tighten pipe connections (ensure proper thread sealant); Inspect and replace internal seals; Replace valve if body is cracked. |

| Valve overheats during operation | Continuous operation exceeding duty cycle; High ambient temperature | Ensure operation adheres to the 10-hour maximum continuous duty cycle; Improve ventilation around the valve if ambient temperatures are high. |

9. Záruka a podpora

U.S. Solid provides a JEDEN ROK ZÁRUKA for this solenoid valve from the date of purchase. If the valve becomes defective within the first year due to manufacturing defects, U.S. Solid will gladly replace it.

For technical support, warranty claims, or inquiries regarding replacement parts, please contact U.S. Solid customer service through their official webwebu nebo prodejce, od kterého byl produkt zakoupen.